Mobillor Digital Warehouse:

Revolutionizing Warehouse Management

Mobillor help to “Revolutionize Your Supply Chain with Our Digital Warehouse Solution: Smart, Efficient, and Future-Ready. Elevate Your warehouse Operations to New Heights!”

Warehouse Management A Rigorous Examination

Complex Inventory Tracking

Traditional systems often grapple with the intricate task of tracking inventory across diverse product lines. The absence of a streamlined mechanism of controlling physical inventory with respect to ERP Systems can lead to inaccuracies, jeopardizing inventory control & overall management.

Manual Data Errors

Without digital warehouse management systems (WMS), relying on manual processes increases the likelihood of errors in tasks such as order picking, inventory tracking, and shipping. This can lead to discrepancies in stock levels, order fulfillment issues, and customer dissatisfaction.

Inefficiency in Operations

Digital warehouse management systems are designed to streamline and automate various warehouse processes. Without them, tasks such as inventory management, order processing, and tracking can be time-consuming and prone to delays, impacting overall operational efficiency.

Inability to Adapt to Industry Trends

The digitalization of warehouses is a key component of Industry 4.0, incorporating technologies such as IoT (Internet of Things), RFID (Radio-Frequency Identification), and automation. Without embracing these technologies, businesses may struggle to keep pace with industry trends and remain competitive.

Limited Visibility and Traceability

Digital WMS provides real-time visibility into inventory levels and movement. Without such systems, businesses may struggle to track and trace products accurately throughout the supply chain. This lack of visibility can lead to difficulties in identifying bottlenecks, optimizing workflows, and responding quickly to changing demands.

Poor Inventory Accuracy

Manual inventory tracking is more prone to errors, leading to discrepancies between recorded and actual stock levels. This can result in stockouts, overstock situations, and difficulties in meeting customer demands, ultimately affecting customer satisfaction and revenue.

Mobillor Digital Warehouse Transformative Approach

1. Effortless Setup and Optimization

Streamline your warehouse setup effortlessly by configuring zones, locations, and preferences, laying the groundwork for an operation that is not just functional but inherently intuitive.

2. Smart Inbound Processes

The inbound process is revolutionized through the integration of Advance Shipment Notifications (ASN) or Goods Receipt Notes (GRN). Material put-away becomes a seamless endeavor through the scanning of QR codes and barcodes or RFID, guided by the Solution’s intuitive interface. The Solution also supports guided put-away, ensuring materials are stored optimally.

3. Streamlined Warehouse Processes

Warehouse processes such as location changes, cycle counts, physical inventory checks, and rejections handling are seamlessly orchestrated within the Solution. Material pick-ups are streamlined through scanning, reducing redundant movements and improving efficiency within the warehouse. Whether it’s pick-ups against production order requirements, dispatch, or warehouse transfer orders, guided pick-ups enhance accuracy and efficiency.

4. Guided Pick-Ups for Precision

Mobillor Digital Warehouse is equipped to enforce lot control, batch control, and serial control during put-away and pick-up processes, ensuring meticulous traceability. Accessible through web and mobile interfaces, the Solution seamlessly integrates with ERPs, supporting industrial mobile devices like Zebra, Honeywell, and Cipher, as well as integration with printers and weigh machines.

5. Meticulous Traceability

With minimal data entry requirements – almost entirely reliant on scanning – Mobillor Digital Warehouse offers real-time visibility into your warehouse, enhancing worker performance monitoring and minimizing errors. By digitizing warehouse operations, the Solution drives substantial benefits for businesses, including a 25% improvement in warehouse labor efficiency, a 60% reduction in data entry time, a 75% decrease in pick-up errors, a 60% reduction in cycle count times, and much more.

Solution Partner Cutting-edge suite of Products

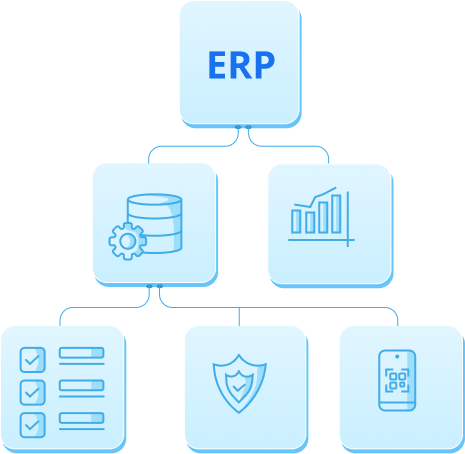

Seamless Integration

Central to its power is the seamless integration adapters connecting to leading ERP systems such as SAP, Oracle, Infor, MS Dynamics, Epicor, SAGE, and Ramco. It further extends its reach by supporting diverse third-party integrations via SOAP, Rest API, and more.

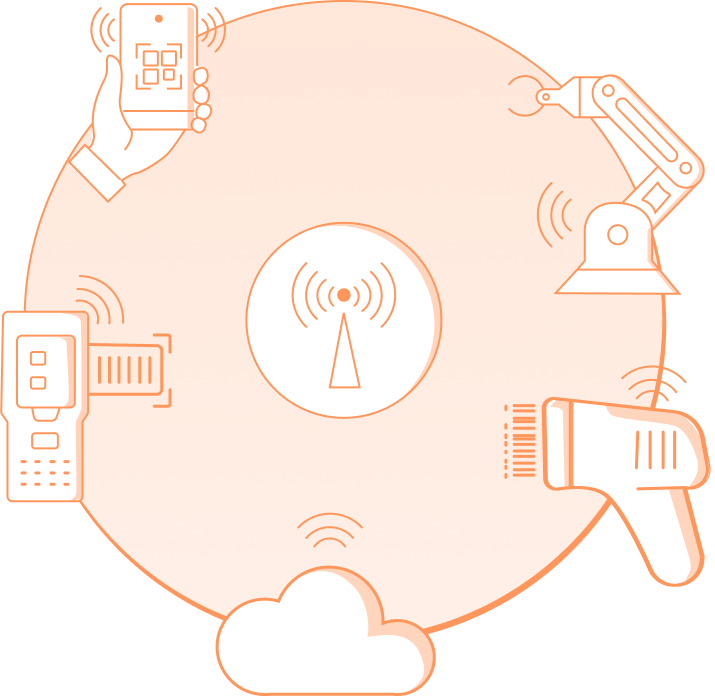

The Mobillor Platform embraces the Internet of Things (IoT) era with an embedded IoT framework, bridging connections to IoT devices using protocols like MQTT, ModBus, and offering comprehensive device management capabilities.

Embracing the realm of machine integration

The Mobillor Platform embraces the Internet of Things (IoT) era with an embedded IoT framework, bridging connections to IoT devices using protocols like MQTT, ModBus, and offering comprehensive device management capabilities.

Embracing the realm of machinery integration, the platform supports various PLC software and machine protocols, including Profibus, Profinet, TCP, and UDP, thus enabling seamless interfacing with machines and PLCs from providers like Siemens, Mitsubishi, Omron, Allen Bradley, and Emerson.

Versatile Database Compatibility and Communication Channels

Traceability is elevated through QR Code, Bar Code, and RFID support, while collaboration with third-party Vision-based AI frameworks extends the platform’s capabilities into the realm of artificial intelligence.

Underpinning the platform’s architecture is the support for Micro Services, fostering modular scalability and adaptability. Deployment is a breeze, whether on cloud or on-premise, with cloud-agnostic capabilities encompassing AWS, Azure, and Google Cloud environments. Load handling and balancing mechanisms ensure optimal performance even under demanding workloads.

Elevating Traceability and AI Integration

The Mobillor Platform truly presents a unified journey for manufacturing enterprises, supporting their entire digital transformation trajectory. Ensuring high availability and efficient mobile device management, the platform also empowers administrators with robust user management capabilities, including integration with Active Directory, advanced access controls, and comprehensive activity tracking.

In essence, the Mobillor Platform redefines manufacturing’s digital horizons, encapsulating innovation, integration, and agility in a single unified ecosystem.