Mobillor Digital Manufacturing helps in

“Transforming Manufacturing Excellence: Embrace the Future with Our Digital Manufacturing Solutions. Smart, Agile, and Efficient – Unleash the Power of Industry 4.0 Today!”

Manufacturing Management A Rigorous Examination

Manual Operation Allocation

In traditional manufacturing, operation tasks are often manually allocated to machine operators, leading to inefficiencies and potential errors in task assignment.

Limited Traceability

Traditional methods may lack meticulous traceability, making it difficult to track materials at each operation stage and ensure quality control.

Disconnected Data Capture in Continuous Manufacturing

Continuous manufacturing processes may suffer from disconnected data capture, hindering accurate tracking of consumption and production data.

Manual Pick List Generation

Traditional methods may involve manual generation of pick lists, leading to delays and errors in material movement within the shop floor.

Limited Operational Insights

Traditional manufacturing approaches may lack real-time insights into shop floor activities, making it challenging to monitor and optimize operations efficiently.

Inefficient Data Entry and Paper-based Activities

Traditional methods often involve time-consuming data entry and reliance on paper-based activities, leading to increased operational costs and potential errors.

Mobillor Digital Manufacturing Transformative Approach

1 Efficient Operation Task Allocation

Mobillor Digital Manufacturing automates operation task allocation based on routing, ensuring efficient and error-free distribution of tasks to machine operators.

2. Enhanced Traceability

Mobillor Digital Manufacturing facilitates the scanning and consumption of materials at each operation, implementing barcodes or QR codes for traceability throughout the entire production processes

3. Seamless Integration

The solution seamlessly integrates with machines, PLCs, and MES systems in continuous manufacturing scenarios, ensuring the accurate capture of consumption and production data.

4. Streamlined Material Movement

Mobillor Digital Manufacturing interacts with Mobillor Digital Warehouse to automatically generate pick lists, streamlining the movement of materials and reducing manual errors.

5. Real-Time Efficiency

With minimal data entry, Mobillor Digital Manufacturing provides real-time insights into shop floor activities, promoting efficient monitoring and optimization, leading to increased productivity.

6. Revolutionizing Operations

Mobillor Digital Manufacturing significantly reduces data entry time by 60%, decreases paper-based activities by 90%, and improves material traceability accuracy by 75%, enhancing overall operational efficiency.

7. Real-Time Monitoring and IoT Sensors

Install IoT sensors on production equipment and manufacturing assets to capture real-time data. Utilize real-time monitoring systems to track the progress of work in progress, machine performance, and overall production efficiency.

8. Shop Floor to Top Floor Integration

Immediate access to the current status of diverse operations, complete insight into production quantities, responsible personnel, quality status, and specific machine centers used. From the boardroom, management can easily ascertain the work in progress and precisely identify each production stage.

9. Cloud-Based Collaboration

Utilize cloud-based collaboration platforms to facilitate real-time communication and data sharing among suppliers, manufacturers, and other stakeholders. Enable secure access to relevant work-in-progress data for authorized parties.

10. Barcode and RFID Technology

Implement barcode and RFID systems for accurate and real-time tracking of materials and products throughout the production process. Enhance traceability by assigning unique identifiers to each work-in-progress item.

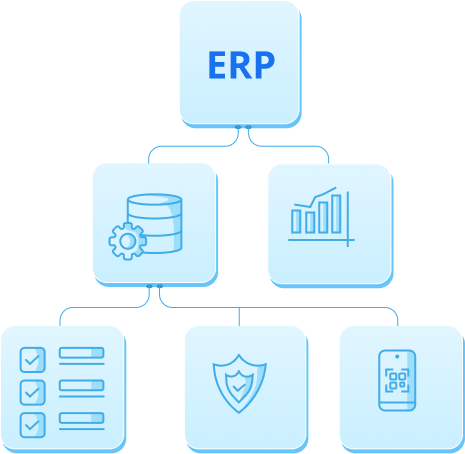

Solution Partner Cutting-edge suite of Products

Seamless Integration

Central to its power is the seamless integration adapters connecting to leading ERP systems such as SAP, Oracle, Infor, MS Dynamics, Epicor, SAGE, and Ramco. It further extends its reach by supporting diverse third-party integrations via SOAP, Rest API, and more.

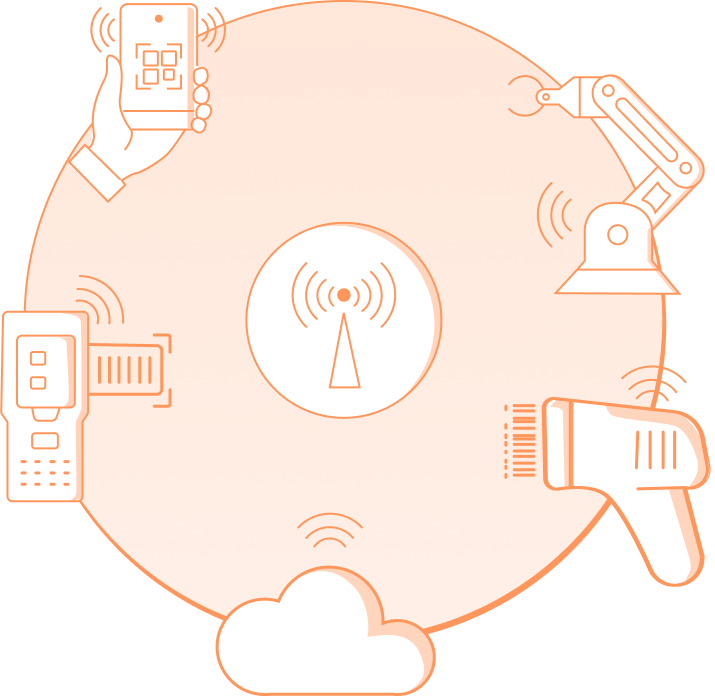

The Mobillor Platform embraces the Internet of Things (IoT) era with an embedded IoT framework, bridging connections to IoT devices using protocols like MQTT, ModBus, and offering comprehensive device management capabilities.

Embracing the realm of machine integration

The Mobillor Platform embraces the Internet of Things (IoT) era with an embedded IoT framework, bridging connections to IoT devices using protocols like MQTT, ModBus, and offering comprehensive device management capabilities.

Embracing the realm of machinery integration, the platform supports various PLC software and machine protocols, including Profibus, Profinet, TCP, and UDP, thus enabling seamless interfacing with machines and PLCs from providers like Siemens, Mitsubishi, Omron, Allen Bradley, and Emerson.

Versatile Database Compatibility and Communication Channels

Traceability is elevated through QR Code, Bar Code, and RFID support, while collaboration with third-party Vision-based AI frameworks extends the platform’s capabilities into the realm of artificial intelligence.

Underpinning the platform’s architecture is the support for Micro Services, fostering modular scalability and adaptability. Deployment is a breeze, whether on cloud or on-premise, with cloud-agnostic capabilities encompassing AWS, Azure, and Google Cloud environments. Load handling and balancing mechanisms ensure optimal performance even under demanding workloads.

Elevating Traceability and AI Integration

The Mobillor Platform truly presents a unified journey for manufacturing enterprises, supporting their entire digital transformation trajectory. Ensuring high availability and efficient mobile device management, the platform also empowers administrators with robust user management capabilities, including integration with Active Directory, advanced access controls, and comprehensive activity tracking.

In essence, the Mobillor Platform redefines manufacturing’s digital horizons, encapsulating innovation, integration, and agility in a single unified ecosystem.