Mobillor Digital Service

Reimagine maintenance practices, elevating them to new levels of efficiency, precision, and prediction.

Services Management A Rigorous Examination

Manual Processes

Traditional management often relies on manual processes, including paper-based documentation and manual data entry. This can lead to errors, delays, and inefficiencies in maintenance operations.

Lack of Real-time Visibility

Traditional management systems may lack real-time visibility for maintenance activities. This can result in a delayed response to issues and an inability to proactively address potential problems.

Limited Data Analysis

Traditional methods may not leverage data analysis effectively. Without the ability to analyze performance parameters and trends, it's challenging to implement predictive maintenance strategies and optimize workflows.

Inefficient Resource Utilization

Managing resources manually can lead to inefficiencies in resource allocation. Without a streamlined system, it's difficult to ensure that the right resources are available when needed, potentially causing delays in repairs and maintenance.

Dependency on Paper

Relying on paper-based operations introduces environmental concerns and is less sustainable. It also makes information retrieval slower and can contribute to the clutter in the workspace.

Fragmented Communication

Traditional management systems may suffer from fragmented communication channels. This can result in a lack of collaboration between maintenance teams and other departments, hindering the overall efficiency of the maintenance processes.

Mobillor Digital Services Transformative Approach

1. Strategic Integration Planning

Develop a well-thought-out integration strategy, leveraging APIs and middleware, to ensure smooth interoperability between various digital platforms and systems. This helps in minimizing disruptions and enhancing overall efficiency.

2. Compliance Management Systems

Implement robust systems for compliance management to navigate data protection regulations effectively. Regularly update policies and procedures to stay in compliance with evolving legal frameworks, ensuring customer trust and avoiding legal consequences.

3. User-Centric Design

Prioritize user experience (UX) and user interface (UI) design to create intuitive, user-friendly digital services. Regularly gather user feedback and conduct usability testing to refine and enhance the overall user experience.

4. Continuous Technological Learning

Establish mechanisms for ongoing education and training to keep teams updated on the latest technological trends. Encourage a culture of continuous learning and innovation to stay ahead of technological changes and leverage emerging opportunities.

5. Digital Inclusion Initiatives

Design digital services with inclusivity in mind, ensuring accessibility for users with diverse needs. Adhere to accessibility standards, conduct regular accessibility audits, and involve diverse user groups in testing to enhance the inclusivity of digital services.

6. Efficient Operation Task Allocation

Mobillor Digital Manufacturing automates operation task allocation based on routing, ensuring efficient and error-free distribution of tasks to machine operators.

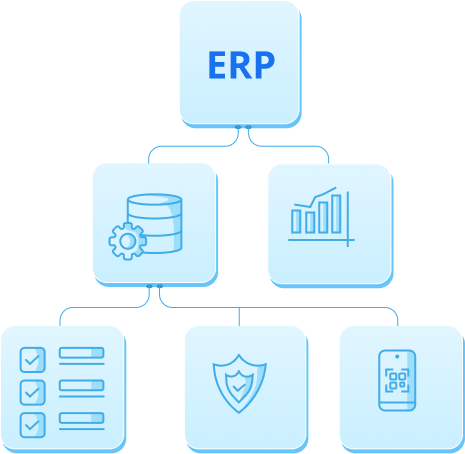

Solution Partner Cutting-edge suite of Products

Seamless Integration

Central to its power is the seamless integration adapters connecting to leading ERP systems such as SAP, Oracle, Infor, MS Dynamics, Epicor, SAGE, and Ramco. It further extends its reach by supporting diverse third-party integrations via SOAP, Rest API, and more.

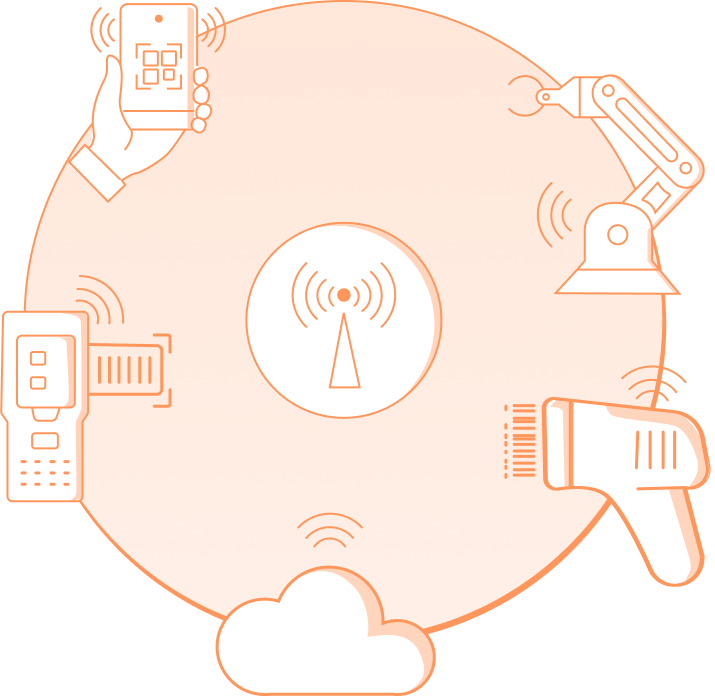

The Mobillor Platform embraces the Internet of Things (IoT) era with an embedded IoT framework, bridging connections to IoT devices using protocols like MQTT, ModBus, and offering comprehensive device management capabilities.

Embracing the realm of machine integration

The Mobillor Platform embraces the Internet of Things (IoT) era with an embedded IoT framework, bridging connections to IoT devices using protocols like MQTT, ModBus, and offering comprehensive device management capabilities.

Embracing the realm of machinery integration, the platform supports various PLC software and machine protocols, including Profibus, Profinet, TCP, and UDP, thus enabling seamless interfacing with machines and PLCs from providers like Siemens, Mitsubishi, Omron, Allen Bradley, and Emerson.

Versatile Database Compatibility and Communication Channels

Traceability is elevated through QR Code, Bar Code, and RFID support, while collaboration with third-party Vision-based AI frameworks extends the platform’s capabilities into the realm of artificial intelligence.

Underpinning the platform’s architecture is the support for Micro Services, fostering modular scalability and adaptability. Deployment is a breeze, whether on cloud or on-premise, with cloud-agnostic capabilities encompassing AWS, Azure, and Google Cloud environments. Load handling and balancing mechanisms ensure optimal performance even under demanding workloads.

Elevating Traceability and AI Integration

The Mobillor Platform truly presents a unified journey for manufacturing enterprises, supporting their entire digital transformation trajectory. Ensuring high availability and efficient mobile device management, the platform also empowers administrators with robust user management capabilities, including integration with Active Directory, advanced access controls, and comprehensive activity tracking.

In essence, the Mobillor Platform redefines manufacturing’s digital horizons, encapsulating innovation, integration, and agility in a single unified ecosystem.