Mobillor Digital Supplier helps to

“Streamline Supplier Collaboration, Enhance Efficiency: Your Gateway to Supplier Collaboration. Simplify, Connect, and Transform Your Supply Chain Today!”

Supplier Management A Rigorous Examination

Manual Processes

Traditional methods often involve manual and paper-based processes for managing supplier information, purchase orders, and communication. This can lead to inefficiencies, errors, and delays.

Limited Transparency

Conventional supplier management may lack real-time visibility into the supply chain, making it challenging to track the status of orders, shipments, and inventory levels accurately.

Communication Barriers

Traditional communication methods, such as emails and phone calls, may result in miscommunication or delayed responses, hindering effective collaboration between manufacturers and suppliers.

Data Silos

Information is often stored in isolated systems, leading to data silos. This fragmentation can impede the seamless flow of information across different departments and hinder decision-making processes.

Lack of Traceability

Traceability of materials and products may be compromised in traditional approaches, making it difficult to quickly identify and address quality issues or track the origin of components.

Inefficient Onboarding

The process of onboarding new suppliers can be time-consuming and prone to errors in a traditional setup. Manual entry of information and documentation may result in delays and increased administrative overhead.

Mobillor Digital Supplier Transformative Approach

1. Real-time Collaboration

Foster seamless communication and collaboration between suppliers and your organization through a digital portal, ensuring instant updates on orders, inventory, and any relevant information.

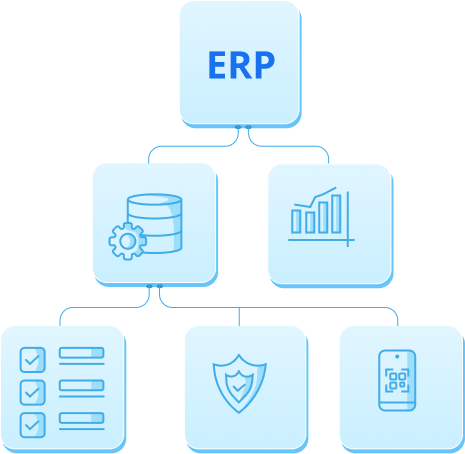

2. Scalability and Integration

Design the digital supplier portal with scalability in mind, allowing for easy expansion as business needs evolve. Additionally, ensure seamless integration with existing enterprise systems, such as ERP and CRM, for a holistic and synchronized business approach.

3. Demand Publishing

Implement a demand forecasting system to predict future demand accurately. And integrate the demand forecasting module with your ERP system to ensure seamless data flow. And Utilize data analytics and machine learning algorithms to enhance demand predictions.

4. Shipment Notification System

Implement an Advanced Shipment Notification (ASN) system to provide real-time information on shipments. And Integrate the ASN system with your ERP and logistics systems for efficient communication. Include details such as shipment contents, expected arrival time, carrier information, transport details with vendor details.

5. Supplier Collaboration

Establish strong relationships with suppliers and communicate the importance of traceability. Ensure suppliers have the necessary technology and processes in place to support traceability.

6. Material Codification and Labeling

Implement a standardized material codification system to uniquely identify each type of material for enabling Traceability. Utilize industry-standard coding systems for consistency and interoperability. Require suppliers to label each item with a unique barcode or RFID tag. Ensure that labeling follows established standards for easy integration with your traceability system.

7. Integration with ERP Systems

Integrate the track and trace system with your Enterprise Resource Planning (ERP) system. Ensure seamless data exchange between the traceability system and other business processes.

8. Supplier Portal

Develop a secure supplier portal where suppliers can input and access traceability data. Include features for uploading material information, labeling details, and shipment data.

9. Real-Time Monitoring

Enable real-time monitoring of material movements from the supplier to your facility. Implement alerts for any deviations or delays in the supply chain.

10. Comprehensive Reporting

Develop reporting tools to generate comprehensive reports on traceability, including material origin, transit times, and any incidents or exceptions.

Solution Partner Cutting-edge suite of Products

Seamless Integration

Central to its power is the seamless integration adapters connecting to leading ERP systems such as SAP, Oracle, Infor, MS Dynamics, Epicor, SAGE, and Ramco. It further extends its reach by supporting diverse third-party integrations via SOAP, Rest API, and more.

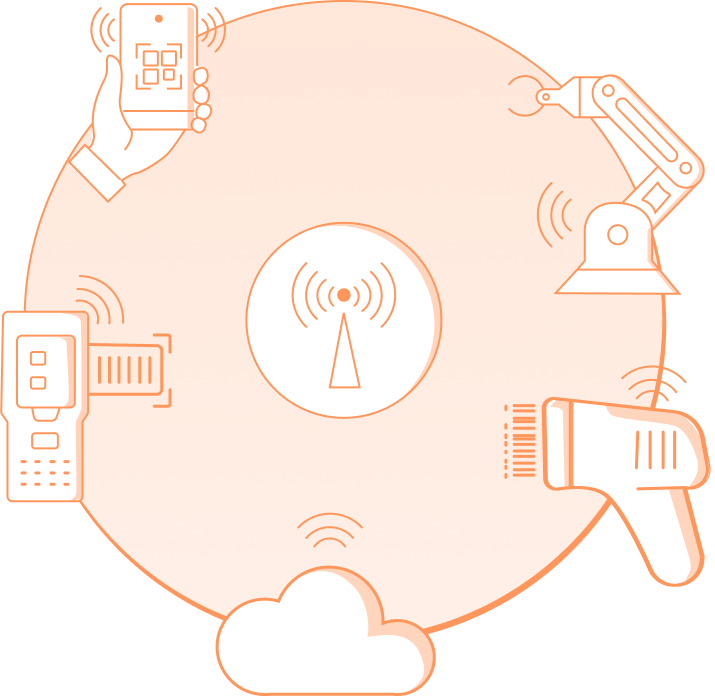

The Mobillor Platform embraces the Internet of Things (IoT) era with an embedded IoT framework, bridging connections to IoT devices using protocols like MQTT, ModBus, and offering comprehensive device management capabilities.

Embracing the realm of machine integration

The Mobillor Platform embraces the Internet of Things (IoT) era with an embedded IoT framework, bridging connections to IoT devices using protocols like MQTT, ModBus, and offering comprehensive device management capabilities.

Embracing the realm of machinery integration, the platform supports various PLC software and machine protocols, including Profibus, Profinet, TCP, and UDP, thus enabling seamless interfacing with machines and PLCs from providers like Siemens, Mitsubishi, Omron, Allen Bradley, and Emerson.

Versatile Database Compatibility and Communication Channels

Traceability is elevated through QR Code, Bar Code, and RFID support, while collaboration with third-party Vision-based AI frameworks extends the platform’s capabilities into the realm of artificial intelligence.

Underpinning the platform’s architecture is the support for Micro Services, fostering modular scalability and adaptability. Deployment is a breeze, whether on cloud or on-premise, with cloud-agnostic capabilities encompassing AWS, Azure, and Google Cloud environments. Load handling and balancing mechanisms ensure optimal performance even under demanding workloads.

Elevating Traceability and AI Integration

The Mobillor Platform truly presents a unified journey for manufacturing enterprises, supporting their entire digital transformation trajectory. Ensuring high availability and efficient mobile device management, the platform also empowers administrators with robust user management capabilities, including integration with Active Directory, advanced access controls, and comprehensive activity tracking.

In essence, the Mobillor Platform redefines manufacturing’s digital horizons, encapsulating innovation, integration, and agility in a single unified ecosystem.